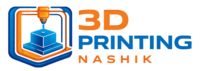

3D printing is powerful, but small mistakes in design or material choice can lead to failed prints, weak parts, or poor surface finish. Understanding the most common 3D printing mistakes helps you save time, material, and cost.

Mistake 1 – Poor Design for 3D Printing

Designs made without considering 3D printing limitations can lead to overhangs, thin walls, and unsupported structures.

How to avoid it:

Use proper wall thickness, add supports where needed, and follow design-for-3D-printing guidelines.

Mistake 2 – Choosing the Wrong Material

Using PLA for a heat-resistant part or ABS for decorative items can cause failures.

How to avoid it:

Select materials based on strength, temperature, and usage conditions.

Mistake 3 – Ignoring Tolerances

Parts that need to fit together require accurate tolerances. Ignoring this leads to parts that are too tight or too loose.

How to avoid it:

Adjust design dimensions and test-fit parts before final production.

Conclusion

Avoiding these common 3D printing mistakes ensures better quality, stronger parts, and smoother production. With the right design, material, and tolerance settings, you can achieve perfect 3D printed results every time.